ANTI FIRE PAINT PLUS

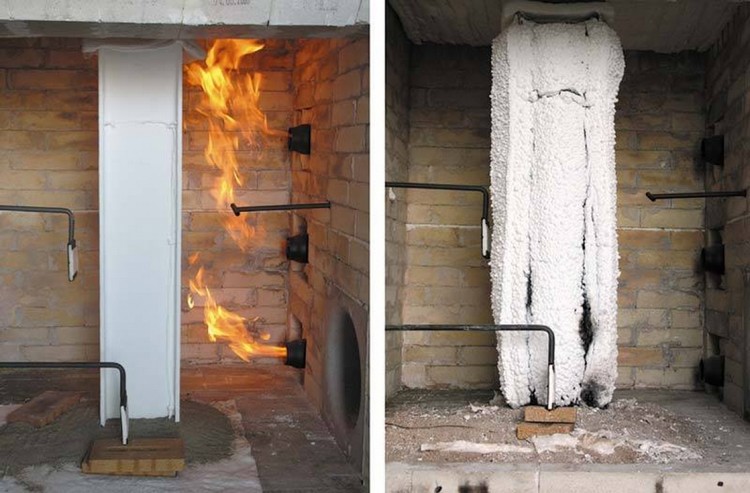

It is a fire-retardant, water based paint that is developed for the protection of the buildings from fire and is fire retardant in the intumescent structure that provides fire insulation via expanding. It forms a seamless layer by drying on the surface on which it is applied. It has excellent flame retardant property, it expands via reacts chemically at the time of the fire and prevents the surface temperature from rising to critical levels. It is water vapor is permeable. Thanks to this feature, it does not prevent the breathing of the surface. It is suitable for use in wood, concrete, prefabricated and steel structures.

TECHNICAL SPECIFICATIONS

pH (25°C): 7.0 - 9.0

Viscosity (25°C, mPa.s): 10000 - 12000

Density (25°C, g/mL): 1,15 ± 0.10

Solid Content (% Weight): 64 ± 2

Solid Content (% Volume): 55 ± 2

Water transmission rate (kg/ m2. h0,5 ) : < 0,1 CLASS W3

Adhesion strength by pull-off test (N/mm2) : Crack bridging flexible systems without trafficking ≥ 0.8

Permeability to water vapour (m) : 5 ≤ SD ≤ 50 CLASS II

Solvent: Water

Applied Standard: EFECTIS ERA EURASIA Testing and Certification Inc. which is accredited by TURKAK, TSE 13501-2: 2016 Fire classification of construction products and building elements - Part 2: Classification using data obtained from fire resistance tests (except ventilation installations). According to the results of the inspection and test report 20.05.2019 dated/EEA-19-063 numbered, in accordance with this standard / TS EN 13381-8: 2013 Test Method for Determination of the Contribution of Structural Components to Fire Resistance - Part 8: According to the test results of Test Method of Reactive Protection Applied to Steel Elements,

Fire Resistance Classes: R15-R20-R30-R45-R60-R90.

ACCORDING TO THE TEST RESULTS OF EFECTIS ERA AVRASYA Test and Certification Inc.; Main Layer Paint (intumescent paint): According to ISONEM ANTI FIRE PAINT PLUS TÜRKAK Accredited Test Report, the results of the evaluation can be applied to all other steel classes and the limitations given here, as specified in EN 10025-1, as specified in Article 6.1 of 13251-4. The results of the assessment can also be applied to fabricated sections. Cross-section factors should be determined according to EN 13381-8: 2013 standard. The results of this assessment are valid for the following conditions of three or four environmental protections.

Cross-section factor: 65 m-1 < Am/V < 527 m-1

Thickness: 1,5 mm < dp < 8,6 mm

Design temperature: 300°C < Qa < 750 °C

Section shape: I, H columns and beams

Documents of the Product

Documents of the Product· All kinds of plastered, painted and unpainted interior and exterior surfaces

· In concrete, wooden and steel structures

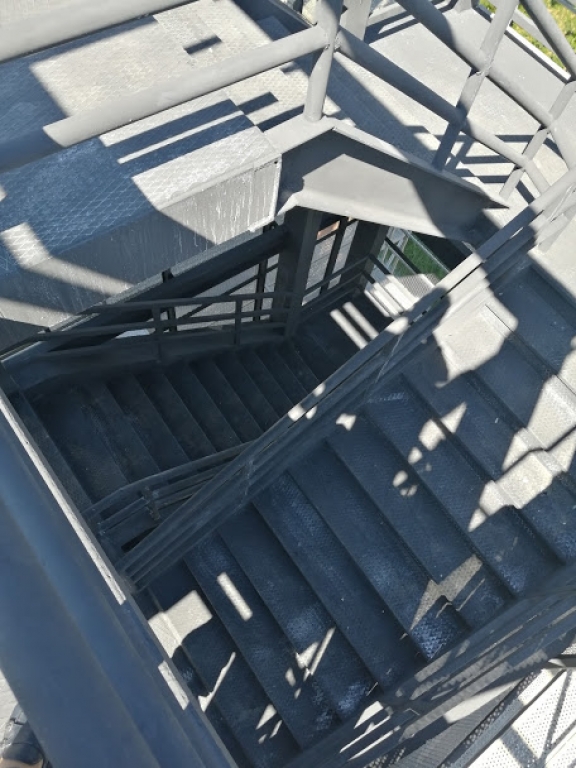

· Roofs, chimneys, fire escape

· In all places where nonflammability is desired

· In schools, kindergartens, hospitals, theaters, and theaters

· Plasterboard wall partitions and ceilings

· Thermal power plants and industrial buildings, factories

· Military Installations

Surface preparation: Surfaces must be clean and dry before application. Oil, dirt, sludge, such as materials should be cleaned, shield particles should be cleaned. The appropriate primer selection depending on the surface is made according to the following table. ISONEM UNIVERSAL PRIMER (1: 7 diluted with water - 1 part primer, 7 part water) insulation and paint primer should be applied one layer with 100 - 200 g/m² consumption. The primer is then allowed to dry for 4 hours. In steel/metal surfaces, the surfaced should be primed with ISONEM Anti Rust Primer (Anticorrosive primer), consumption of 0,250 - 0,350 kg/m².

Application method: It can be made by brush, roller or a suitable sprayer. It should be mixed until homogenous before use. After the application of primer, it is applied to the surface in two coats 4 hours apart without diluted and the painting process is nished. In exterior applications and in indoor applications that are exposed to water, and high humidity, ISONEM ANTI FIRE PAINT is applied as a topcoat with a brush, roller or a suitable sprayer with consumption of 0.3-0.5 kg/m². In steel/metal surfaces, the surfaced should be primed with ISONEM Anti Rust Primer (Anticorrosive primer), consumption of 0,250 - 0,350 kg/m².

COLOR: All requested can be produced in colors.

CONSUMPTION: 3,5 kg/m² for 1,5 mm thickness, steel structures (Surface / material thickness / depending on the desired fire retardant resistance time vary)

PAINTABLE (COVERAGE) AREA: 3,5 - 5 m²/5 kg bucket, 7 - 5 m²/10 kg bucket, 12,5 - 18 m²/18 kg bucket

PACKING: 5,10,18 kg PP in bucket.

SHELF LIFE: 24 months from date of production if stored in original, unopened, undamaged packages.

STORAGE CONDITIONS: Store tightly closed in a dry and cool place.

IMPORTANT: The surface should be protected from rain, water, mechanical loads and impacts for 24 hours during and after the application.

Français

Français Español

Español русский

русский العربية

العربية Deutsch

Deutsch